ART. 106P

APPLICAZIONE:

La valvola di ritegno a palla ha la funzione di impedire il riflusso di fluidi viscosi, densi e con materiali in sospensione. Si può installare sia in posizione orizzontale che verticale, purché la direzione del fluido a valvola aperta avvenga nella direzione indicata dalla freccia. La temperatura massima ammessa per il fluido è di 70°C mentre la pressione massima di esercizio ammessa è di 16 bar, tranne che per il DN 250 e DN 300 che é di 10 bar. La tenuta viene realizzata tramite l’azione di una sfera gommata. Non è adatta all’utilizzo con fluidi aggressivi.

CARATTERISTICHE COSTRUTTIVE:

La sfera è rivestita in gomma sintetica NBR. Per il modello filettato le filettature sono secondo ISO 228. Per il modello flangiato, gli ingombri sono realizzati secondo le prescrizioni della norma EN 558-1. Le flange sono forate secondo la norma EN 1092-2.

La valvola è progettata per avere il passaggio totale in posizione di completa apertura e minime perdite di carico. Verniciatura epossidica spessore medio 250 µ.

N.B. In caso di utilizzo con acqua potabile l’impianto deve avere almeno una pressione di 2 Bar.

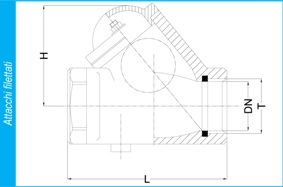

| Attacchi Filettati | ||

| DN | COD | |

| 1″ | 5000FF | |

| 1″ 1/4 | 5001FF | |

| 1″ 1/2 | 5002FF | |

| 2″ | 5003FF | |

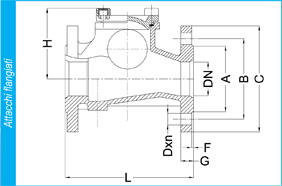

| Attacchi Flangiati | ||

| DN | COD | |

| 50 | 5010FL | |

| 65 | 5011FL | |

| 80 PN 10 | 5012FL | |

| 80 | 5013FL | |

| 100 | 5014FL | |

| 125 | 5015FL | |

| 150 | 5016FL | |

| 200 PN 10 | 5017FL | |

| 200 | 5018FL | |

| 250 PN 10 | 5019FL | |

| 300 PN 10 | 5020FL | |

| Corpo, Coperchio | Ghisa grigia EN-GJS-250 |

| Rivestimento sfera | NBR |

| Tappo corpo/coperchio | NBR |

NORMA DI PROGETTO: UNI EN 1074-3

[spoiler title=”Attacchi filettati” open=”1″ style=”2″] [/spoiler]

[/spoiler]

[spoiler title=”Attacchi flangiati” open=”0″ style=”2″] [/spoiler]

[/spoiler]

NB. Dimensioni in mm e peso in Kg

| Dn | L | H | T | Peso |

| Attacchi Filettati | ||||

| 25 | 120 | 75 | 1″ | 2 |

| 32 | 140 | 75 | 1″ 1/4 | 3 |

| 40 | 150 | 89 | 1″ 1/2 | 4 |

| 50 | 220 | 113 | 2″ | 5 |

| Attacchi Flangiati | ||||

| 50 | 200 | 113 | 8 | |

| 65 | 240 | 126 | 12 | |

| 80 | 260 | 162 | 17 | |

| 100 | 300 | 194 | 23 | |

| 125 | 350 | 214 | 37 | |

| 150 | 400 | 260 | 53 | |

| 200 | 500 | 320 | 99 | |

| 250 | 600 | 365 | 136 | |

| 300 | 700 | 427 | 220 | |